The incorporation of tube bends in fluid system design is important from many different perspectives – procurement, installation and performance. Modern processes are pushing pressure, flow, and temperature requirements to new heights every day, yet the basic concepts of system design have not changed over the years. Leaks that were once considered nuisances are now classified as fugitive emissions and hazardous spills, problems that can shut down plants. The demands placed on today’s fluid systems are much tougher than they were a decade ago.

Instrument tube bending serial#

This data may be downloaded to a personal computer through a serial port connection on the side of the tool. aerospace tube installation) where individual tube fitting data are archived for safety and quality control purposes. This is useful in high-reliability production environments (e.g. For standard industrial Swagelok compression fitting sizes ( 1/4 inch, 3/8 inch, and 1/2 inch), the recommended swaging rotation of 1-1/4 turns may be entered into the tool as a tightening angle of 450 degrees:īeing a microprocessor-controlled device, the SX-1 has the ability to digitally record all actions. The amount of rotation is programmable, enabling the tool to be used with different kinds of fittings. This next pair of photos shows how the tool is able to support itself on a piece of stiff ( 1/2 inch stainless steel) tubing, and indeed may even be operated hands-free: In such an environment, torque applied to the tool operator could be disastrous, as the human operator has no weight to stabilize herself. Not only does this feature reduce the amount of stress placed on the tube fitter’s hand and wrist, but it also enables the tool to be used in the demanding environment of zero gravity, for example aboard a space station. The tool comes complete with a holding jig to engage the body of the tube fitting, in order that all tightening torque is borne by the tool and not imposed on the person operating the tool: The Tube Bending Machine (Aeroswage SX-1) has a microprocessor-controlled electric motor programmed to rotate a tube fitting’s nut to a precise angular dimension, in order to properly swage the fitting. One of these special devices is an electronic power tool manufactured by American Power Tool expressly for use with instrument tube fittings: Special tubing toolsĪ variety of specialized tools exist to help tubing installers work with compression-style tube fittings. When bending such a loop, it is helpful to use the circumference of a large pipe as a mandrel to form the tube rather than attempt to form a loop purely by hand. An example of a vibration loop placed in the air supply tube going to a control valve appears in this photograph:

Instead, a vibration loop should be made in the tube, giving it the necessary elasticity to tolerate the vibrational stresses. If an instrument tube must connect between a stationary object and a vibrating object, a straight (square) run of tube is actually not desirable, since it will not have much flexibility to absorb the vibration. A photograph of several tube junctions shows one way to do this: The philosophy here, as always, is to build the tubing system with future work in mind. When multiple tube unions must be placed in parallel tube runs, it is advisable to offset the unions so it is easier to get a wrench around the tube nuts to turn them. Long runs of instrument tubing made from standard 20 foot tube sections, however, require junctions be made somewhere, usually in the form of tube unions. Connections invite leaks, and leaks are problematic.

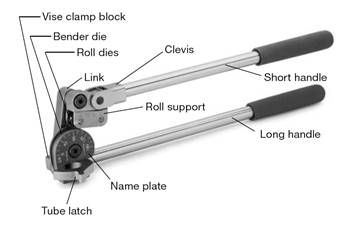

If possible, a goal in tube bending is to eliminate as many connections as possible. It is truly magnificent to see a professionally-crafted array of stainless steel instrument tubes, all bends perfectly made, all terminations square, all tubes parallel when laid side by side and perfectly perpendicular when crossing. Tube bending is something of an art, especially when done with stainless steel tubing.

0 kommentar(er)

0 kommentar(er)